Over 30 percent of facility downtime in commercial buildings stems from preventable HVAC equipment failures, driving up operational costs worldwide. For operations managers in larger HVAC firms, the push for automation has never felt more urgent as reliable asset management means healthier profit margins and satisfied clients. This overview reveals how automation empowers companies to predict issues, optimise maintenance, and achieve unmatched reliability in even the most complex building portfolios.

Table des matières

- Defining Automation in Modern Asset Management

- Types of Automation for HVAC Asset Management

- How Automation Streamlines Maintenance Workflows

- Predictive Maintenance and Real-Time Analytics

- Benefits, Cost Impacts, and Return on Investment

- Common Pitfalls and Integration Challenges

Principaux enseignements

| Point | Détails |

|---|---|

| Significance of Automation | Automation is crucial for modern asset management, transforming operations from reactive to predictive models that enhance efficiency. |

| Types of Automation Technologies | Key approaches like Automated Fault Detection and Diagnostics (AFDD) and Maintenance 4.0 leverage IoT, AI, and data analytics to optimise HVAC performance. |

| Predictive Maintenance Advantages | Implementing predictive maintenance strategies significantly reduces downtime and extends equipment lifecycles through data-driven insights. |

| Financial and Operational Benefits | Advanced automation in HVAC can lead to energy savings of 15–38%, longer equipment lifespan, and improved regulatory compliance, delivering substantial ROI. |

Defining Automation in Modern Asset Management

Modern asset management represents a profound technological transformation in how organisations track, monitor, and optimise their critical infrastructure. Automation has emerged as a pivotal strategy, enabling businesses to transition from reactive maintenance approaches to intelligent, data-driven operational models. By integrating advanced technologies, companies can now generate real-time insights, predict potential equipment failures, and streamline complex maintenance workflows.

At its core, automation in asset management involves deploying sophisticated software platforms, sensor technologies, and artificial intelligence to continuously monitor equipment performance and health. Comprehensive AI optimization techniques are now enabling HVAC systems to operate with unprecedented precision, tracking critical parameters such as temperature, humidity, energy consumption, and mechanical stress in real-time. These systems can automatically detect anomalies, generate maintenance alerts, and even recommend preemptive interventions before significant equipment degradation occurs.

The technological ecosystem driving modern asset management automation encompasses several interconnected components. These include Internet of Things (IoT) sensors, cloud computing infrastructures, machine learning algorithms, and integrated management platforms. By synthesising data from multiple sources, organisations can create holistic views of their asset performance, enabling more strategic decision-making. Predictive maintenance strategies now allow technicians to schedule interventions based on actual equipment conditions rather than arbitrary time-based maintenance windows, dramatically reducing unnecessary downtime and repair costs.

Conseil de pro : Implement a phased automation strategy that begins with pilot programmes in specific operational zones, allowing your organisation to build expertise and demonstrate tangible value before comprehensive rollout.

Types of Automation for HVAC Asset Management

Automation in HVAC asset management encompasses a diverse range of technological approaches designed to enhance operational efficiency, reduce maintenance costs, and optimise system performance. These automation strategies have evolved dramatically, transforming traditional reactive maintenance models into intelligent, predictive management systems that can anticipate and prevent potential equipment failures before they occur.

One of the most sophisticated automation approaches is Automated Fault Detection and Diagnostics (AFDD), which integrates Building Information Modelling (BIM) technologies to create comprehensive diagnostic models. This advanced system enables facility managers to develop sophisticated detection mechanisms that can identify subtle equipment irregularities, track performance trends, and generate precise maintenance recommendations. By leveraging complex data analysis and machine learning algorithms, AFDD systems can pinpoint potential issues with remarkable accuracy, allowing for targeted and proactive interventions.

Another critical automation type emerging in the HVAC sector is the Maintenance 4.0 framework, which synthesises multiple cutting-edge technologies. This approach integrates Internet of Things (IoT) sensors, artificial intelligence, machine learning algorithms, and big data analytics to create a holistic maintenance ecosystem. Such systems continuously monitor equipment performance, collecting real-time data that enables condition-based maintenance strategies. By analysing vibration patterns, temperature fluctuations, energy consumption, and other critical parameters, these intelligent platforms can predict potential equipment failures with unprecedented precision, dramatically reducing unexpected downtime and extending asset lifecycles.

Conseil de pro : Prioritise gradual automation implementation by first identifying critical HVAC assets that would benefit most from advanced monitoring technologies, allowing for strategic, cost-effective digital transformation.

Here is a comparative overview of key automation approaches in HVAC asset management:

| Automation Approach | Technologies Integrated | Typical Benefits |

|---|---|---|

| AFDD | BIM, machine learning | Early fault detection, precise interventions |

| Maintenance 4.0 | IoT sensors, AI, big data | Condition-based maintenance, reduced downtime |

| Predictive Maintenance | Real-time analytics, historical data | Failure prevention, optimised scheduling |

How Automation Streamlines Maintenance Workflows

Modern HVAC maintenance workflows have undergone a radical transformation, moving from manual, reactive processes to intelligent, proactive systems that dramatically reduce operational inefficiencies. Automation technologies now enable organisations to predict, prevent, and manage equipment maintenance with unprecedented precision and effectiveness, fundamentally reshaping how technical teams approach asset management and system reliability.

Advanced automation technologies are revolutionising maintenance strategies by integrating artificial intelligence, Internet of Things (IoT) sensors, and machine learning algorithms into cohesive operational frameworks. These intelligent systems continuously monitor equipment performance, collecting real-time data that allows for immediate diagnostic insights and predictive interventions. By analysing complex parameters such as temperature variations, vibration patterns, energy consumption, and mechanical stress, automated systems can generate precise maintenance recommendations, schedule targeted interventions, and significantly reduce the likelihood of unexpected equipment failures.

The integration of automated workflows brings multiple strategic advantages to HVAC asset management. Intelligent systems can automatically generate work orders, track maintenance history, prioritise repair tasks, and provide comprehensive documentation with minimal human intervention. Real-time monitoring enables technicians to receive instant alerts about potential issues, allowing for rapid response and preventative maintenance. This approach not only minimises downtime but also extends equipment lifecycles, reduces overall maintenance costs, and improves the reliability of critical HVAC infrastructure.

Conseil de pro : Implement a phased automation strategy by first instrumenting your most critical HVAC assets with IoT sensors, enabling gradual digital transformation and demonstrating tangible operational improvements.

Predictive Maintenance and Real-Time Analytics

Predictive maintenance represents a quantum leap in HVAC asset management, transforming traditional reactive approaches into sophisticated, data-driven strategies that anticipate potential equipment failures before they occur. By leveraging advanced technologies, organisations can now move beyond periodic inspections and emergency repairs, creating a proactive maintenance ecosystem that maximises system reliability and operational efficiency.

AI-based predictive maintenance techniques have revolutionised how organisations monitor and manage HVAC systems. These intelligent approaches integrate Internet of Things (IoT) sensors, machine learning algorithms, and real-time data analytics to continuously assess equipment health. By analysing complex performance parameters such as vibration patterns, temperature fluctuations, energy consumption, and mechanical stress, these systems can detect subtle anomalies that might indicate impending equipment failures, enabling targeted interventions before critical breakdowns occur.

The core strength of predictive maintenance lies in its ability to transform raw operational data into actionable insights. Advanced machine learning models, including sophisticated techniques like autoencoders, can process vast amounts of historical and real-time data to create comprehensive health prognostics for HVAC systems. These models learn from previous maintenance records, performance trends, and environmental conditions, developing increasingly accurate predictive capabilities. Technicians can now receive precise recommendations about potential equipment issues, optimal maintenance scheduling, and expected component lifecycles, dramatically reducing unplanned downtime and extending overall system reliability.

Conseil de pro : Establish a baseline performance dataset for your HVAC assets by collecting comprehensive operational metrics over several months, creating a robust foundation for implementing effective predictive maintenance strategies.

Benefits, Cost Impacts, and Return on Investment

The implementation of advanced automation technologies in HVAC asset management represents a strategic investment with substantial financial and operational benefits. By transforming traditional maintenance approaches, organisations can achieve significant cost reductions, improved system performance, and enhanced operational efficiency that deliver measurable returns across multiple dimensions of business performance.

Building Automation and Control Systems offer remarkable economic advantages, with potential energy consumption reductions ranging from 15% to 38%. These systems generate rapid financial returns, typically achieving full investment payback within 1–3 years. Beyond immediate cost savings, organisations benefit from improved Energy Performance Certificate ratings, increased asset valuation, and enhanced compliance with increasingly stringent energy regulations.

The comprehensive benefits of HVAC automation extend far beyond direct energy savings. Intelligent systems dynamically adjust operations based on real-time environmental data, optimising equipment performance while simultaneously reducing mechanical wear and extending asset lifecycles. By minimising unnecessary system operations and enabling precise, condition-based maintenance, organisations can dramatically reduce utility expenses, lower carbon footprints, and create more sustainable operational frameworks. Additional advantages include improved indoor environmental quality, enhanced occupant comfort, and more predictable maintenance scheduling, which collectively contribute to significant long-term organisational value.

Conseil de pro : Conduct a comprehensive baseline energy audit before implementing automation systems to accurately measure and document potential performance improvements and financial returns.

The following table summarises financial and operational impacts of automation in HVAC management:

| Impact Area | Automation Benefit | Business Outcome |

|---|---|---|

| Energy Efficiency | 15–38% reduction in consumption | Lower utility costs, improved sustainability |

| Lifecycle Extension | Reduced mechanical wear | Durée de vie plus longue des équipements |

| Compliance | Enhanced regulatory adherence | Fewer legal and audit issues |

Common Pitfalls and Integration Challenges

The journey towards comprehensive HVAC automation is fraught with complex technological and organisational challenges that can significantly impede successful implementation. Organisations must navigate a intricate landscape of technical, strategic, and operational barriers to realise the full potential of advanced maintenance technologies, requiring sophisticated planning and nuanced understanding of potential integration obstacles.

Maintenance 4.0 implementation challenges reveal multiple critical barriers organisations must address. Data quality represents a fundamental obstacle, with many systems struggling to generate reliable, consistent operational insights. Organisations frequently encounter issues with model interpretability, where advanced algorithms produce recommendations that lack transparent reasoning. Scalability concerns further complicate automation efforts, as systems must flexibly adapt across diverse operational environments while maintaining consistent performance and reliability.

Technical integration challenges extend beyond data management, encompassing complex infrastructure compatibility and communication protocol limitations. Legacy HVAC systems often lack standardised interfaces, creating significant interoperability challenges that can result in fragmented, inefficient automation implementations. These compatibility issues frequently manifest as increased implementation costs, extended deployment timelines, and suboptimal system performance. Successful integration demands a holistic approach that considers not just technological capabilities, but also organisational readiness, user training, and long-term strategic alignment.

Conseil de pro : Conduct a comprehensive systems audit and compatibility assessment before automation implementation, identifying potential integration points and technical limitations in your existing infrastructure.

Unlock the Full Potential of HVAC Automation with Proven Asset Management Solutions

The article highlights the complex challenges organisations face when adopting automation in HVAC asset management—from data inconsistencies to integration issues with legacy infrastructure. You want smarter workflows that leverage predictive maintenance and real-time analytics without the headache of siloed systems or unreliable data. Achieving reliable, proactive HVAC management demands an intelligent platform that unites equipment monitoring, work order management, and operational visibility under one roof.

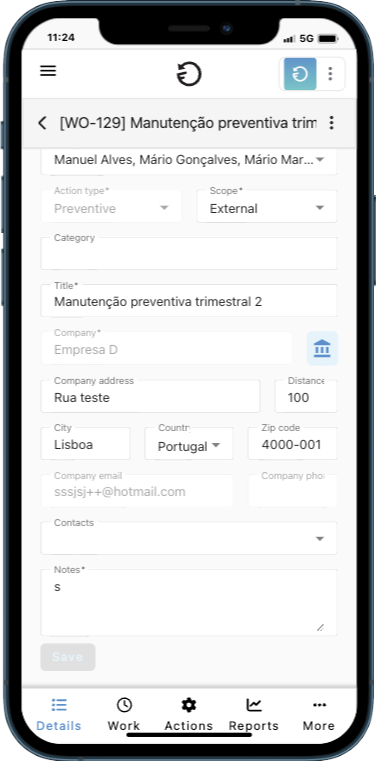

Discover how FullyOps addresses these pain points by streamlining asset lifecycle management and field services through advanced automation tools tailored for HVAC and other critical sectors. Our SaaS solution supports condition-based workflows, automated documentation, et real-time insights empowering technicians, back-office teams, and managers to reduce downtime and control maintenance costs effectively. Don’t let integration challenges hold you back. Take the next step to optimise your maintenance strategy and experience rapid returns by visiting FullyOps. Unlock efficiency gains and transform your HVAC asset management today.

Questions fréquemment posées

How does automation improve HVAC asset management?

Automation enhances HVAC asset management by integrating advanced technologies such as IoT sensors, AI, and machine learning. This allows for real-time monitoring, predictive maintenance, and data-driven decision-making, significantly reducing downtime and improving system efficiency.

What are the key benefits of predictive maintenance in HVAC systems?

Predictive maintenance utilises real-time data analytics to anticipate equipment failures before they occur. This approach minimises unplanned downtime, optimises maintenance schedules, and extends the lifespan of HVAC systems, ultimately resulting in cost savings and improved performance.

What is Automated Fault Detection and Diagnostics (AFDD) in HVAC?

AFDD is an advanced automation approach that leverages Building Information Modelling (BIM) and machine learning to identify subtle equipment anomalies, track performance trends, and generate precise maintenance recommendations, thus preventing potential equipment failures.

How can companies effectively implement automation in HVAC management?

Companies can effectively implement automation by adopting a phased strategy that begins with pilot programs in critical operational zones. This method allows organisations to build expertise, showcase tangible value, and gradually transition to comprehensive automation.

Recommandé

Améliorez vos opérations et maximisez votre efficacité avec FullyOps

- Pour les équipes de maintenance

- Assurez le bon déroulement des opérations grâce à la gestion automatisée des ordres de travail, au suivi en temps réel et à la coordination transparente entre les équipes.

- Pour les prestataires de services

- Optimisez l'efficacité des services sur le terrain grâce à une programmation intelligente, une planification des ressources et des outils conviviaux pour une gestion mobile.

- Pour les gestionnaires d'actifs

- Bénéficiez d'une visibilité totale sur les cycles de vie des actifs, les calendriers de maintenance préventive et le suivi de la conformité, le tout en un seul endroit.