Most operations managers face mounting pressure to reduce asset downtime and extend equipment lifespans. In fact, businesses lose up to 10 percent of annual revenue to unforeseen breakdowns and manual tracking errors. With automated asset tracking, HVAC companies gain real-time visibility into equipment health and maintenance needs. This article explores how modern digital solutions streamline asset management, boost reliability, and help organisations avoid costly disruptions across global markets.

Table of Contents

- Automated Asset Tracking Explained Clearly

- Key Technologies In Modern Asset Tracking

- Real-World Applications In Field Operations

- Productivity, Cost, And Compliance Impacts

- ROI And Common Pitfalls To Avoid

Key Takeaways

| Point | Details |

|---|---|

| Automated Asset Tracking | Enhances organisational efficiency by digitising asset management and reducing human error. |

| Technological Innovations | Integrate RFID, IoT sensors, and AI to provide real-time visibility and predictive insights. |

| Field Service Benefits | Improves technician productivity and optimises resource allocation through instant access to data. |

| Implementation Considerations | Focus on training, system integration, and change management to maximise ROI and avoid pitfalls. |

Automated Asset Tracking Explained Clearly

Automated asset tracking represents a sophisticated digital approach to monitoring and managing organisational resources with unprecedented precision. At its core, this technology transforms how businesses understand, utilise, and maintain their critical equipment and infrastructure. Comprehensive asset management systems enable organisations to track hardware and software assets in real-time, providing unparalleled visibility into their operational ecosystem.

The fundamental purpose of automated asset tracking is to centralise and digitise asset information, eliminating traditional manual record-keeping methods prone to human error. Modern systems integrate advanced technologies like barcode scanning, radio-frequency identification (RFID), and GPS tracking to capture precise location, usage, maintenance history, and performance metrics for each asset. By creating a comprehensive digital profile, businesses can make data-driven decisions about resource allocation, maintenance scheduling, and lifecycle management.

Field service organisations particularly benefit from these systems, gaining instant insights into equipment status, technician assignments, and potential maintenance requirements. Asset tracking frameworks help prioritise maintenance activities, predict potential failures, and optimise resource utilisation. This approach reduces unexpected downtime, extends equipment lifespan, and significantly improves operational efficiency across diverse industrial sectors.

Pro tip: Start by conducting a comprehensive audit of your current asset inventory to establish a baseline for your automated tracking implementation.

Key Technologies In Modern Asset Tracking

Modern asset tracking has evolved dramatically, driven by a suite of sophisticated technological innovations that transform how organisations monitor and manage their critical resources. Advanced tracking technologies now combine multiple digital solutions to create comprehensive, real-time asset management ecosystems that go far beyond traditional inventory methods.

Radio-frequency identification (RFID) technology stands at the forefront of these innovations, enabling precise asset location tracking and instant data capture. Complementing RFID, Internet of Things (IoT) sensors provide granular insights into asset performance, condition, and usage patterns. These sensors can monitor everything from equipment temperature and vibration to operational hours and maintenance requirements, generating continuous streams of actionable data that help organisations make informed strategic decisions.

Artificial intelligence and machine learning algorithms have further revolutionised asset tracking by transforming raw data into predictive insights. Consolidated tracking systems now integrate advanced software platforms that can anticipate maintenance needs, predict potential equipment failures, and optimise resource allocation with unprecedented accuracy. These intelligent systems create comprehensive digital profiles for each asset, tracking its entire lifecycle and supporting more efficient operational planning across various industrial sectors.

Pro tip: Select asset tracking technologies that offer seamless integration with your existing operational infrastructure to maximise implementation effectiveness.

Here is a comparison of key asset tracking technologies and their business advantages:

| Technology | Main Function | Business Benefit |

|---|---|---|

| Barcode Scanning | Item identification and tagging | Basic asset control and auditing |

| RFID | Wireless location and data capture | Real-time visibility, rapid updates |

| IoT Sensors | Performance and condition monitoring | Predictive maintenance, lower downtime |

| GPS Tracking | Asset movement and location tracking | Field deployment and security |

| AI/Machine Learning | Data analysis and prediction | Strategic planning, failure prevention |

Real-World Applications In Field Operations

Field service operations represent a complex ecosystem where precise asset tracking can dramatically transform organisational efficiency. Asset tracking platforms now provide sophisticated solutions that enable real-time monitoring and management of equipment across diverse operational environments, from remote construction sites to intricate industrial facilities.

In practical terms, modern asset tracking technologies support field technicians by providing instant access to critical equipment information. Mobile interfaces allow technicians to retrieve comprehensive service histories, diagnostic details, and maintenance records with a few simple taps. This immediate access eliminates time-consuming manual record searches and reduces the potential for errors that can occur when relying on paper-based documentation systems. The ability to track assets in real-time means organisations can optimise resource allocation, reduce unnecessary equipment downtime, and make more informed strategic decisions about maintenance and replacement schedules.

Field service management systems have revolutionised how organisations approach equipment lifecycle management. These intelligent platforms integrate multiple data streams, combining GPS tracking, sensor diagnostics, maintenance logs, and predictive analytics to create a holistic view of organisational assets. Technicians can now receive proactive maintenance alerts, understand equipment performance trends, and make data-driven recommendations about repair, replacement, or optimization strategies. This approach transforms field operations from reactive problem-solving to strategic, predictive management that minimises disruptions and maximises operational efficiency.

Pro tip: Implement a standardised asset tagging system that integrates seamlessly with your mobile tracking platform to ensure comprehensive and consistent data collection.

Productivity, Cost, And Compliance Impacts

Automated asset tracking delivers transformative benefits that extend far beyond simple record-keeping, fundamentally reshaping organisational performance through enhanced operational productivity and compliance management. By eliminating manual data entry processes and providing real-time asset insights, these technologies create substantial economic advantages that directly impact an organisation’s bottom line.

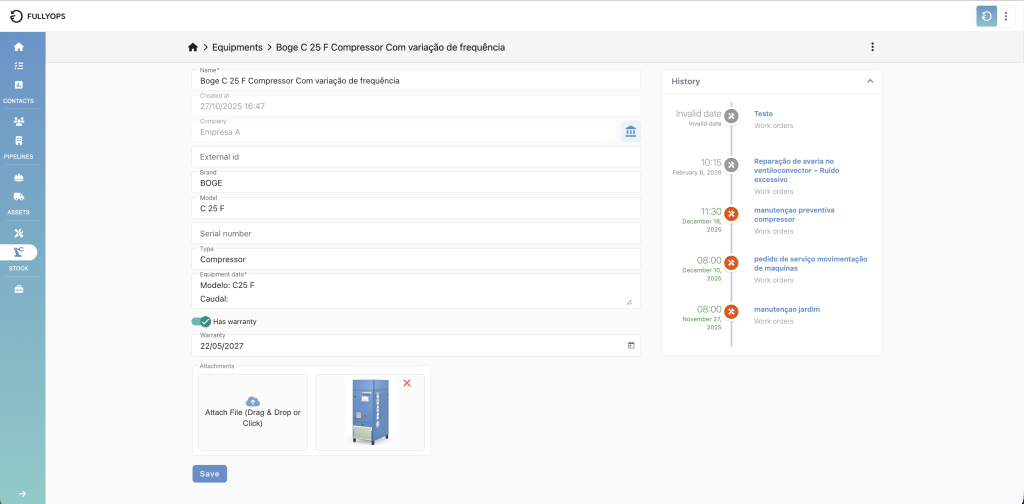

![]()

From a productivity perspective, automated tracking systems dramatically reduce time spent on administrative tasks, allowing field service technicians to focus on critical operational activities. Manual inventory management typically consumes hours of productive time, introducing significant opportunities for human error and inefficiency. Automated systems streamline these processes, generating instant reports, tracking asset locations, and providing comprehensive maintenance histories with minimal human intervention. This efficiency translates directly into reduced labour costs and increased technician productivity, enabling organisations to accomplish more with existing resources.

Compliance represents another crucial domain where automated asset tracking delivers substantial organisational value. Accuracy and regulatory compliance become significantly more manageable when comprehensive, real-time digital records replace fragmented paper-based systems. Automated platforms create detailed audit trails, track asset movements, document maintenance activities, and ensure organisations maintain meticulous records that withstand regulatory scrutiny. These systems provide transparent, verifiable documentation that can protect organisations from potential legal and financial risks associated with non-compliance.

Pro tip: Conduct a comprehensive baseline audit of your current asset management processes before implementing automated tracking to identify specific improvement opportunities.

ROI And Common Pitfalls To Avoid

Successful implementation of asset tracking technologies requires a strategic approach that balances technological investment with measurable organisational outcomes. Maximising ROI from asset tracking demands comprehensive planning that goes beyond simply purchasing new software or hardware. The most successful organisations approach this transformation as a holistic business strategy, carefully aligning technological capabilities with specific operational requirements.

Several critical pitfalls can undermine the potential benefits of asset tracking systems. The most significant risks include inadequate staff training, poor system integration, and selecting technologies that do not align with existing operational workflows. Many organisations mistakenly view asset tracking as a purely technological solution, overlooking the human elements critical to successful implementation. This approach often leads to low user adoption, inefficient system utilisation, and diminished return on investment. Successful deployment requires a balanced approach that combines technological innovation with robust change management strategies.

The following table summarises common pitfalls in asset tracking implementation, alongside solutions:

| Pitfall | Impact on Organisation | Solution Strategy |

|---|---|---|

| Inadequate Training | Low system adoption rates | Comprehensive onboarding |

| Poor System Integration | Data silos and workflow gaps | Unified platform selection |

| Wrong Technology Fit | Ineffective operations | Needs-focused assessment |

| Lack of Change Management | Resistance to new processes | Proactive staff engagement |

| Insufficient Feedback | Slow improvements | Regular progress reviews |

Financial considerations extend beyond initial implementation costs. Organisations must conduct thorough cost-benefit analyses that account for long-term efficiency gains, reduced maintenance expenses, and improved asset utilisation. The true value of asset tracking emerges through incremental improvements in operational efficiency, reduced downtime, and more strategic resource allocation. Sophisticated tracking systems can generate substantial financial returns by providing insights that enable proactive maintenance, optimise equipment lifecycle management, and minimise unnecessary capital expenditures.

Pro tip: Develop a comprehensive implementation roadmap that includes pilot testing, phased rollout, and continuous feedback mechanisms to ensure successful asset tracking adoption.

Transform Your Field Service Operations with FullyOps Automated Asset Tracking

The challenges of manual asset management and inefficient workflows highlighted in the article can lead to costly downtime and compliance risks. FullyOps understands the need for real-time visibility, predictive maintenance, and seamless integration of asset data with field operations. With its intelligent SaaS platform designed for medium to large organisations, FullyOps helps you eliminate human errors, optimise resource allocation, and extend asset lifecycles. By digitising asset management and automating workflow processes, you empower your technicians, managers, and back-office teams with the tools that the article describes as essential for field service success.

Experience the benefits of integrating advanced asset tracking concepts like real-time status, maintenance histories, and predictive analytics into your daily operations. Explore FullyOps solutions that streamline work orders and accelerate decision-making while reducing operational costs and risks.

Ready to evolve from reactive to proactive asset management with a platform tailored to the challenges described in “Why Automate Asset Tracking for Field Service Success”? Request a demo and discover how your organisation can achieve greater efficiency and compliance through intelligent automation.

Frequently Asked Questions

What is automated asset tracking?

Automated asset tracking is a digital system that monitors and manages organisational resources, using technologies like barcode scanning, RFID, and GPS to provide real-time visibility into assets’ locations, usage, and maintenance history.

How does automated asset tracking improve field service operations?

It enhances field service operations by providing technicians with instant access to critical equipment information on mobile devices, optimising resource allocation, reducing downtime, and enabling data-driven decision-making regarding maintenance and replacement schedules.

What key technologies are involved in modern asset tracking?

Modern asset tracking involves several key technologies, including RFID for precise localisation, IoT sensors for performance monitoring, and AI for predictive analytics, all of which together create a comprehensive asset management system.

What are the main benefits of automating asset tracking for compliance?

Automated asset tracking improves compliance by replacing manual record-keeping with accurate, real-time digital records, creating detailed audit trails that ensure organisations meet regulatory requirements and reducing the risk of non-compliance.

Recommended

Enhance Your Operations and Maximize Efficiency with FullyOps

- For Maintenance Teams

- Ensure smooth operations with automated work order management, real-time tracking, and seamless coordination between teams.

- For Service Providers

- Optimize field service efficiency with smart scheduling, resource planning, and mobile-friendly tools for on-the-go management.

- For Asset Managers

- Gain full visibility into asset lifecycles, preventive maintenance schedules, and compliance tracking—all in one place.